Efficient, sustainable, inspired by nature

Freudenberg Filtration Technologies’ newly developed spiderMaxx cassette filters offer turbomachinery operators maximum performance and operational reliability.

The only way to avoid costly machine downtime and losses in efficiency is to ensure that the intake air for gas turbines and compressors is free of dust and moisture. This also reduces unnecessary CO2 emissions and has a positive impact on climate protection and the operators’ footprint.

Freudenberg Filtration Technologies’ innovative new spiderMaxx cassette filters offer all of the aforementioned advantages. Their premium filtration performance ensures clean air in gas turbines for power plants and oil rigs as well as in compressors for a range of industrial applications, e.g. air separation plants. spiderMaxx cassette filters offer this performance over a long period of time with unprecedented availability and reliability even at full load and during load peaks. They are EPA (Efficient Particulate Air) filter class and feature an increased dust holding capacity and a service life that is around 25 percent longer than the previous standard cassette filter life.

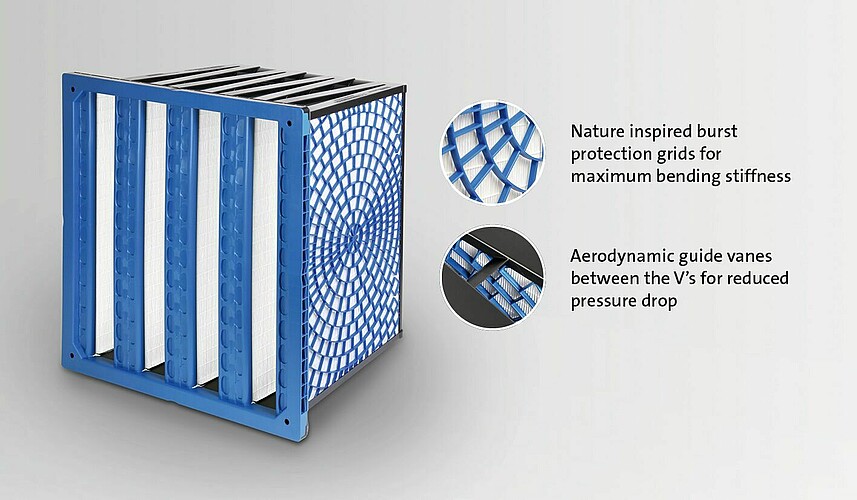

The excellent performance of the new spiderMaxx cassette filters is due to a series of refinements to the design. The transfer of phenomena from nature to technological applications is called bionics. Spider webs’ naturally robust design and structure have an extremely high level of resistance. These graceful structures stand up to wind, weather, and insects flying into them at full force.

The spider web is an excellent role model for spiderMaxx cassette filters. Inspired by nature, the leakproof casting of this innovative filtration solution features extremely high dimensional stability and resilience. The concentric spider web design of the casting distributes the fluctuating variable mechanical loads that occur during operation across the entire filter frame. This means that the filters can withstand extremely adverse environmental conditions, even those in stormy coastal and offshore regions.

Setting leakproofing standards

The filter frame, which comprises one-piece front and back plates, sets the standard for mechanical stability and torsional rigidity. The frame is optimally sealed to prevent dust from penetrating. The sophisticated design, which features an integrated channel in the front frame, ensures that the foamed-on gasket fits perfectly, even in critical areas, such as filter corners. The overall leakage risk is close to zero. Water slopes also provide effective water drainage towards the air entry side.

The aerodynamic guide vanes between the v-shaped pleat packages provide a contribution to sustainability. They ensure a low-turbulence airflow and effectively contain vortex formation on the downstream side. This ensures minimal flow resistance and reduced pressure drop, which results in lower CO2 emissions during operation.

Turbomachinery usually uses multi-stage filtration systems (gradually arranged filter types arranged in two, and in many cases three filter stages). When combined, they first filter moisture, followed by coarser particles, and finally fine dust from the intake air. As the final filter stage, the new spiderMaxx cassette filter is the cherry on top of the cake of the complete filtration system. As a high-end filter, it is responsible for efficient filtration of the finest particles. Its high-performance water-repellent filter medium means the filter can withstand moisture even when used on its own, making it ideal for use in high humidity areas.

spiderMaxx and calculating filter efficiency with e.FFECT

Freudenberg Filtration Technologies’ clip-on system makes it possible to connect the individual filter stages of a filtration system easily and in a space-saving manner. In the case of the spiderMaxx cassette filter, an integrated gripping lug and rounded shatterproof contours also guarantee simple, safe handling.

The filter specialists at Freudenberg Filtration Technologies use decades of experience and digital support to determine which filter combination is right for the particular application. They use simulation software, the electronic Freudenberg Filter Efficiency Calculation Tool (e.FFECT), to compare possible solutions and configure individually optimized intake air filtration systems for turbomachinery operators. This is because the more specifically a filtration system is tailored to the respective system requirements, the more powerful, safe, efficient, and economical the operation of the entire turbomachinery system. spiderMaxx cassette filters should be part of any filtration system that requires maximum performance and operational reliability.