Filter monitoring with Viledon Process View

Your solution for efficient tracking and management of filter systems

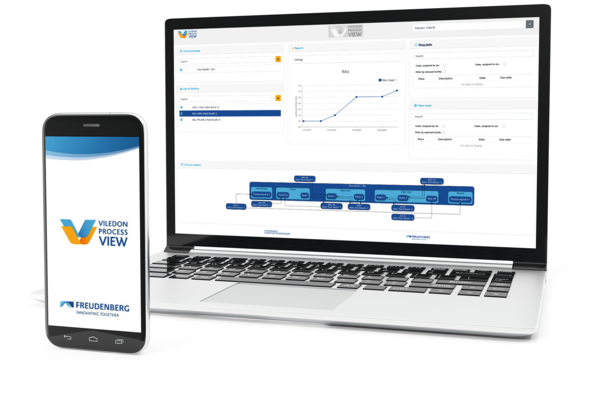

Viledon Process View offers you a digital solution for managing your filter systems. With the user-friendly software platform and the matching app, you can maintain an overview: Monitor filter statuses, detect filter problems promptly and minimize downtimes with efficient maintenance planning.

Simplify maintenance tasks with Viledon Process View

Viledon Process View digitizes the maintenance process of industrial filter systems by recording the system and its filter stages once. Viledon filterCair service technicians or internal maintenance engineers can use a mobile app on their phone and QR codes on the respective filter systems to easily document the filter changes and measurements carried out and receive automatic notifications when maintenance work is required. Tasks can be created, photos uploaded and data sheets for the installed filters can be viewed quickly and easily. Recorded data is transferred in real time to the software platform, where it is analyzed and evaluated to identify potential problems at an early stage. By using advanced analysis algorithms, Viledon Process View can provide precise recommendations for action to minimize downtime and reduce operating costs. The data management system is continuously developed to meet your requirements.

Improve your processes with digital filter administration

Increased efficiency

Viledon Process View enables optimized supervision and advanced management of filter systems, resulting in increased operational efficiency and reduced operating costs.

Improved product quality

By continuously observing filter systems, Viledon Process View ensures consistently high product quality and contributes to compliance with industry standards.

Reduced downtime

By detecting filter problems early and providing accurate alerts, Viledon Process View helps to minimize downtime and ensure production continuity.

Efficient maintenance planning

With the digital support of Viledon Process View, you can plan and carry out maintenance work efficiently, leading to a reduction in downtime and costs.

Audit security and data protection

The standardized documentation of filter service life and changes provides audit security, while data protection is ensured by the independent development and management of the Freudenberg Filtration Technologies data management system.

Find out how you can optimize your filter systems with Viledon Process View. Contact us for a free consultation.

Application areas

Surface technology, beverage and food production, metal and plastic processing, air conditioning and ventilation systems, the chemical industry and many more: Viledon Process View is essential for companies in various industries to increase the efficiency of their filter systems and minimize downtimes. It is used wherever air needs to be filtered:

Paintshops

The Viledon Process View is particularly important for paint stores, as it enables continuous control of the numerous filter systems and filter stages, thus helping to ensure consistently high coating quality. Paint damage caused by airborne contaminants is avoided thanks to the digital system.

Find out more about our filters and services for industrial painting.

Food industry

In the food and beverage industry, the quality of air filtration is crucial for product quality and compliance with hygiene regulations. Viledon Process View ensures reliable monitoring of filtration systems to ensure compliance with standards, assure product safety and minimize product contamination.

Discover our filtration solutions for food and beverage production.

Power generation

In energy production, clean air and efficient filter systems are essential for smooth operation and pollution prevention. The Viledon Process View enables proactive surveillance of gas turbine and compressor filtration systems to reduce operating and energy costs and minimize environmental impact.

Discover our filtration solutions for gas turbines and compressors.

Clean Rooms

For the pharmaceutical industry, hospitals, bio- and nanotechnology and semiconductor manufacturing, air quality control is of major importance. Viledon Process View provides oversight of filter systems to ensure that cleanroom conditions are maintained at all times.

Learn more about our filter solutions and services for cleanrooms and pharma.

Gas Phase Filtration

Gas phase filters are essential for corrosion protection of electronic components and for odor and VOC control. Using Viledon Process View ensures high air quality, product and workplace safety and compliance with environmental regulations.

Find out more about filtration solutions to protect sensitive areas from harmful gases.

Battery manufacturing

With the increasing demand for lithium-ion batteries, the use of Viledon Process View in battery manufacturer is essential to ensure efficient and high quality production and success in an increasingly competitive market.

Learn more about application optimized air filtration solutions for battery manufacturing.